Micro Pearl Mayco Stoneware Glaze

Description

What are Mayco Micro Glazes?

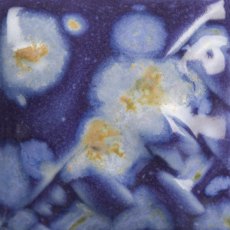

"Micro" is short for "microcrystalline" which is a glaze that develops small crystallization from the the zinc and silica during the cooling process. Micros do not actually contain a glass crystal like our other stoneware crystal glazes. Rather, the effect is created by the glaze itself during the firing process. These glazes can be fired from cones 5-10, but the crystallization may not form at higher temperatures. The micros are not dinnerware safe due to surface durability, with the exception of the Micro Pearl. We recommend using micros on the outside of dinnerware, below the lip line or on decorative wares.

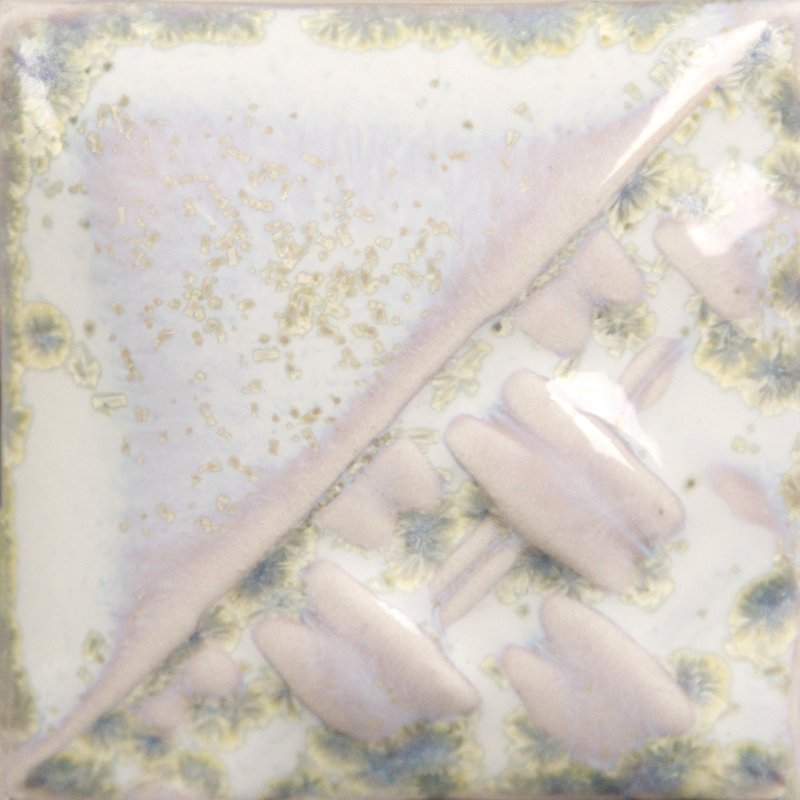

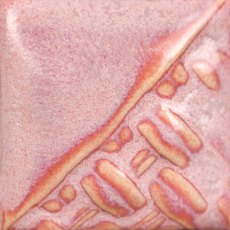

1230°C (1st image): Micro Pearl is a glossy, semi-opaque white glaze with lilac undertones that breaks over texture. Iridescent micro-crystallization in shades of lilac and pale yellow will develop during the firing process.

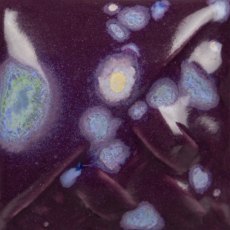

1300°C (2nd image): Glaze darkens to blue, purple and white variegation.

Tip: This glaze is stable at 3 coats. Additional coats or increased application thickness may result in movement. We recommend firing our micro glazes to cone 6 oxidation to reach crystalline development. Micro-Pearl achieves a stable, semi-opaque, frosted white result with a pearlescent satin finish when fired to cone 5. Can be used in oxidation or reduction firings. Results may vary. The choice of clay body, thickness of application, firing process, and temperature will greatly affect the fired results. Always test your application on your clay body in your kiln environment.

Health & Safety

Manufacturers Recommendations: Dinnerware Safe indicates the fired glaze surface meets the FDA standards for food safe, the fired surface is free of surface texture that could potentially trap bacterial, and the fired surface is chemically durable. Please note, dinnerware safety is not defined by cutlery scratches. Finished ware producers bear responsibility for dinnerware safe testing their ware being sold into commerce.

We at Bath Potters will quote the manufacturers recommendations, but if you intend to make ceramic dinnerware with selling in mind, then you would be best advised to get your wares tested.

Lucideon: https://www.lucideon.com/testing-characterization/ceramic-testing-analysis

Northern Testhouse: https://www.nthleicester.co.uk/service/homewares

Customer Reviews

Collect in Store

This item is available for collection.

Share

Micro Pearl Mayco Stoneware Glaze

Facebook Twitter Email Pinterest Telegram