Glaze & Body Powdered Stains

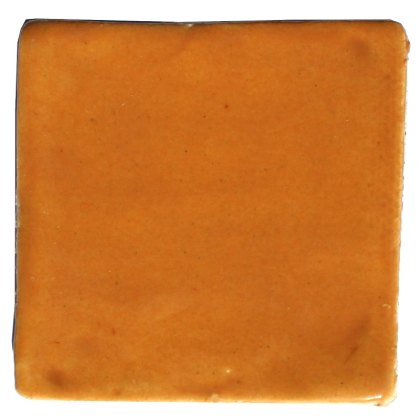

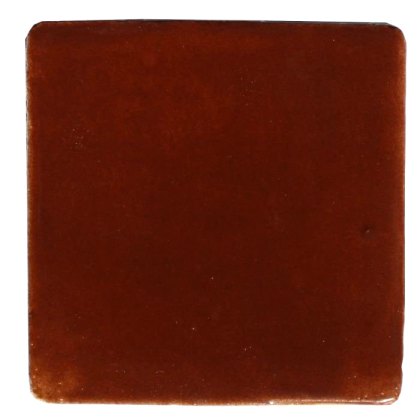

Autumn Brown Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.08 inc VAT

Azure Blue Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.37 inc VAT

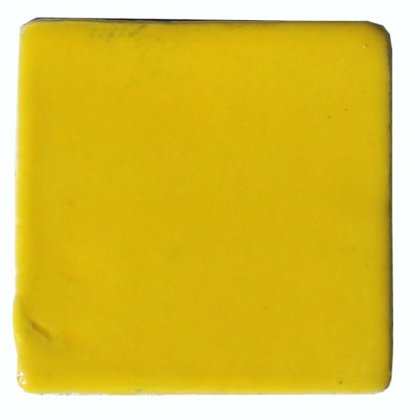

Banana Yellow Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.51 inc VAT

Black Glaze & Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £6.68 inc VAT

Charcoal Chrome Free Black Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £4.75 inc VAT

Chrome Tin Pink Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £4.93 inc VAT

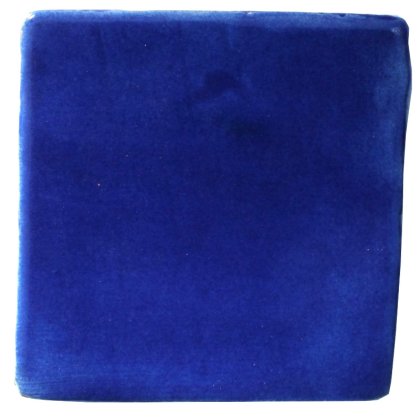

Cobalt Blue Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £10.68 inc VAT

Coral Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.00 inc VAT

Cornflower Blue Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £7.61 inc VAT

Crimson Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £5.16 inc VAT

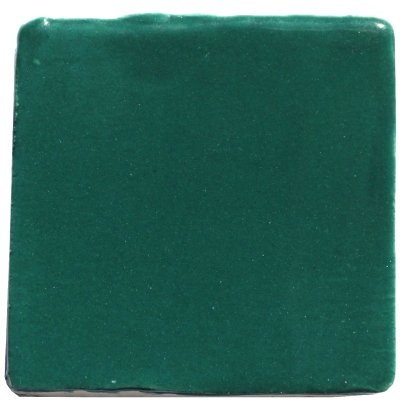

Emerald Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.67 inc VAT

Forest Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.19 inc VAT

Grey Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.36 inc VAT

High Fire Black Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Cobalt Blue Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Coral Pink Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Crimson Red Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.88 inc VAT

High Fire Jaffa Orange Inclusion Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.65 inc VAT

High Fire Lemon Yellow Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Maroon Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Paprika Orange Inclusion Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.71 inc VAT

High Fire Peacock Blue Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Pink Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £1.43 inc VAT

High Fire Purple Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.60 inc VAT

High Fire Raspberry Red Inclusion Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.88 inc VAT

High Fire Red Brown Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £1.71 inc VAT

High Fire Tango Orange Inclusion Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.57 inc VAT

High Fire Turquoise Blue Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.14 inc VAT

High Fire Yellow Inclusion Glaze Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.51 inc VAT

High Temp Red Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

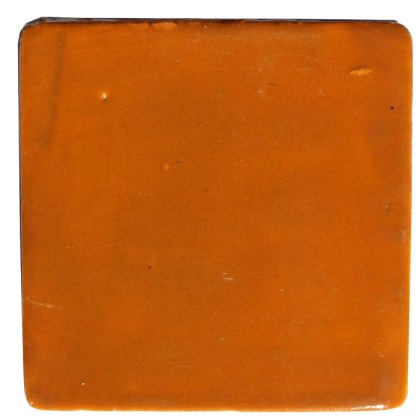

Honey Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.06 inc VAT

Lime Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.59 inc VAT

Maize Yellow Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.99 inc VAT

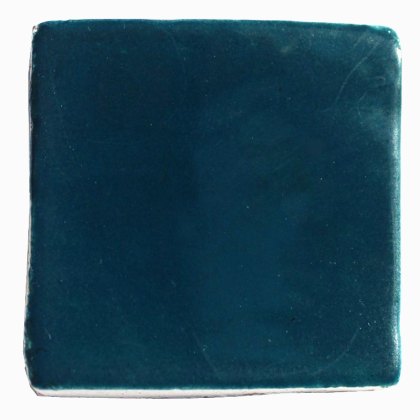

Marine Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.01 inc VAT

Mazarine Blue Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £10.61 inc VAT

Nut Brown Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.73 inc VAT

Orange Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.12 inc VAT

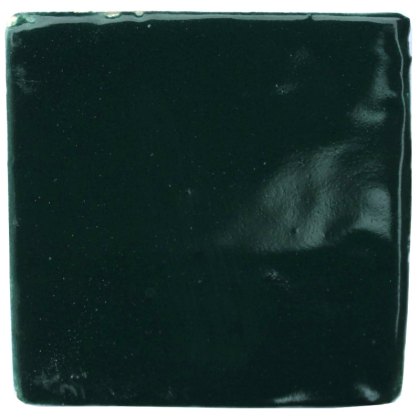

Persian Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £6.73 inc VAT

Pitch Black Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £5.80 inc VAT

Purple Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £6.52 inc VAT

Rose Pink Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £4.50 inc VAT

Sepia Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.37 inc VAT

Sun Yellow Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.51 inc VAT

Tan Brown Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.89 inc VAT

Tan Pink Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.21 inc VAT

Turquoise Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £2.53 inc VAT

Turquoise Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.18 inc VAT

Victoria Green Glaze & Body Stain

Our glaze and body stains are made of a combination of oxides and frits that create beautiful uniform rich colors. You can add stains to glaze recipes to produce color in an opaque or transparent base glaze, (5-8% addition). They can also be added to decorating slip (10-18% addition), engobes, and even clay to make coloured clay bodies. Stains can also be mixed with water to create washes that add...

from £3.27 inc VAT