Glaze Trouble Shooting

Crawling

Crawling is where the molten glaze withdraws into islands leaving bare clay patches. The edges of the islands are thickened and smoothly rounded. In moderate cases there are only a few bare patches of clay, in severe cases the glaze forms beads on the clay surface and drips off onto the shelf.

Solutions:

- Reduce the presence of oil, grease and dust by reducing handling of bisque ware and use damp sponge to clean pots before glazing. If you are using underglaze powders mix with Universal Medium instead of water

- Slow initial firing stage to allow moisture and impurities to burn away, keep the kiln ventilated until 400°C then add bung.

- Cracking of glaze layer during drying can cause crawling. Also, ensure the glaze layer is completely dry before firing

Blistering

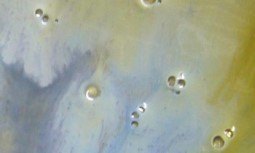

Blistering appears as a pronounced, sharp-edged burst bubble and looks like a crater on the fired glaze surface, often revealing the underlying bisque pottery or clay body and sharp edges around the blister. Pinholes result in tiny craters with soft edges; blisters result in slightly larger craters with sharp edges.

Blisters can also show up as a rough, grainy, blistered, bubbled, cratered or surfaces with "holes" or bald patches in the glaze following firing. Sometimes the glaze or fired piece looks like it is covered in large bubbles similar to honeycomb.

Solutions

- Thinner glaze application.

- Longer drying time between glazing and firing.

- Check kiln for over firing.

- Increase soak time up to 30 minutes and consider holding the soak at a slightly lower temperature.

- Make sure the glaze and clay have compatible firing temperatures.

Pinholing

This is where small holes appear in the glaze when impurities in the clay aren’t burnt out during the bisque firing, causing them to escape during the glaze firing.

Solutions;

Try bisque firing slightly hotter; if possible, hotter than the glaze firing, to make sure all impurities are burnt out. A bisque fire to 1060C should burn out most impurities.

Use a 100mesh sieve when mixing up your glaze

Apply a thinner glaze

Leave an inch between pots when stacking the kiln

Crazing

Crazing takes the form of fine cracks spread over the glaze. They can be so fine they're often hard to detect, especially on coloured glazes. Crazing causes moisture to enter the clay body making it porous and unhygienic.

The fundamental cause for crazing is the difference in contraction between the glaze and clay body

Causes for crazing;

Underfiring- the most common cause for crazing. The ware needs to be fired above the minimum recommended for the body. Most potters biscuit fire around 1000°C but for buff or earthenware bodies need to be fired to 1100°C in order to mature body and glaze. Refiring the crazed ware can often clear the problem provided the glaze can withstand the higher temperature.

Insufficient heatwork-Over firing or firing too quickly can cause crazing. A firing cycle of 100-120°C per hour is the norm for studio potters.

Low expansion clay body- use of a low expanision body can craze a normal balenced glaze e.g. stoneware/ porcelain/ raku bodies fired at earthenware temperatures will probably craze the glaze. If the body cannot be fired higher consider an addition of flint or cristobalite to the body

High expansion glaze- if the thermal expansion of a glaze is too high crazing is inevitable. The addition of silca (flint or quartz) can reduce this

Glazing too thickly- the thinner the glaze coat the better the craze resistance.

Use of unmatched engobes or slip- crazing may appear over the areas of decoration

Addition of metal oxides to the glaze will increase the thermal expansion to avoid this you may need to fire higher or soak longer

Heat shock-ideally you should wait until the ware load is room temperature before opening the kiln. Certainly, kilns should not be opened while the kiln is over 200°C

Shivering

Shivering is the most problematic of glaze defects, particularly in any functional ware, since slivers of glaze from the edges can drop into food or drink. These slivers are usually small, sharp, jagged-edged pieces that detach themselves from the body. It is the most dangerous of glaze faults. Shivering is the reverse of crazing, therefore the remedies are the opposite as well:

Solutions

1. decrease the silica in either the body or the glaze

2. increase the feldspar, especially sodium feldspar or nepheline syenite, or other alkaline bearing materials.